+7 (495) 702-94-83

Our products

Flexibility of thought. Plasticity of material.

It’s all about inimitable german plastic “Gebau Kunststoff”

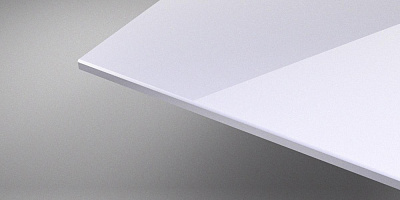

High-impact polystyrene (HIPS) – product of the copolymerization of styrene with butadiene rubber, which adds elasticity and impact strength.

Polystyrene (also known as PS) is a thermoplastic polymerization product of styrene monomer. It is one of the most widely used materials.

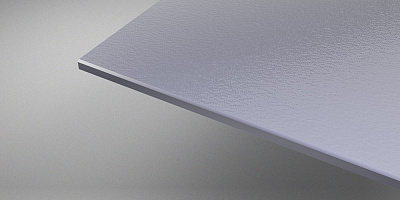

Sheet material produced by coextrusion of two layers - ABS (high impact strength, elasticity, thermoformability) and PMMA (high transparency, gloss, surface hardness, wear resistance).

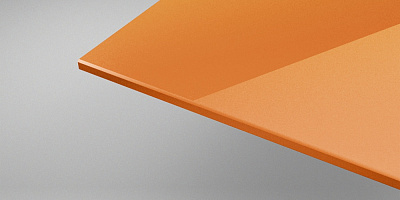

Acrylonitrile butadiene styrene (ABS) – is a thermoplastic polymer with glass transition temperature of around 100°С. ABS is an amorphous polymer.

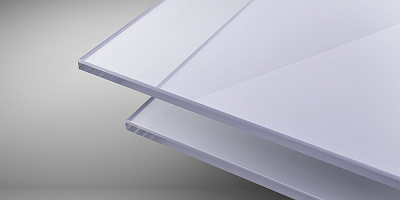

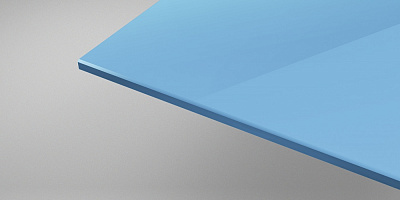

PMMA (Polymethylmethacrylate) also known as acrylic or acrylic glass is a transparent thermoplastic material with light transmittance of 92%.

Polyethylene terephthalate (PET) - It is a thermoplastic esterification product of terephthalic acid. One of the most common polyesters.