Our products

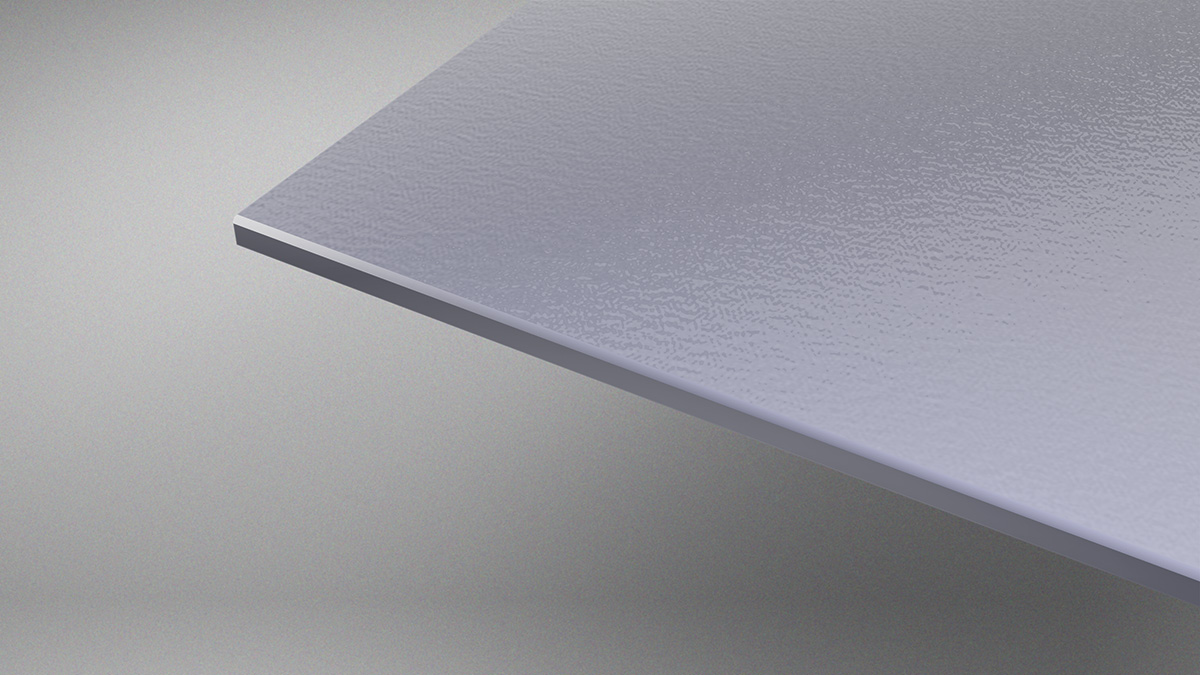

ABS

Acrylonitrile butadiene styrene (ABS) – is a thermoplastic polymer with glass transition temperature of around 100°С. ABS is an amorphous polymer.

By composition, ABS is a terpolymer produced by polymerizing styrene and acrylonitrile along with polybutadiene. Typically, the ratio of components varies from 15 to 35% of acrylonitrile, 5 to 30% of butadiene and 40-60% of styrene. As a result, a structure is obtained in which the elastomer (rubber) particles are distributed in a solid polymer matrix. Due to this factor ABS becomes more durable, compared to pure polystyrene.

- Acrylonitrile imparts high rigidity, heat and chemical resistance.

- Butadiene, being an elastic component, provides impact strength and frost resistance

- Styrene monomer ensures shiny surface and manufacturability

This way the selection of the optimum component ratio at the synthesis stage helps to create the necessary complex of required properties of the final ABS polymer.

ABS is a structural material with an excellent balance of stiffness and impact strength.

ABS is resistant to aqueous solutions of acids and alkalis, concentrated chloric and phosphoric acids, alcohols, animals, vegetable and mineral oils. ABS swells in glacial acetic acid, carbon tetrachloride 4-aromatic hydrocarbons. It is also not resistant to concentrated sulfuric and nitric acids, soluble in esters, ketones, dichlorideethylene and acetone.

Long exposure to sunlight leads to deterioration in properties and discoloration (yellowing) of ABS, therefore the material requires additional modification by UV stabilizers and antioxidants, for use in the exterior.

- High impact strength

- High thermoformability

- High frost resistance

- Excellent balance of stiffness and impact strength

- Advertising

- Body parts of electrical appliances

- Commercial equipment, household and industrial refrigerators

- Details of the interior and exterior of cars, agro-industrial machinery, special machinery

- Construction